Efficient Methods for Accomplishing Ideal Foam Control in Chemical Manufacturing

Efficient foam control is a critical element of chemical production that can dramatically impact manufacturing efficiency and product high quality. By understanding the mechanisms of foam development and choosing appropriate anti-foaming representatives, suppliers can take positive steps to alleviate excessive foam. Additionally, the application of process optimization strategies and advanced surveillance systems plays an important role in maintaining ideal operating conditions. Nevertheless, the subtleties of these methods can differ extensively throughout various applications, raising vital questions about finest methods and real-world applications that warrant further exploration.

Recognizing Foam Formation

Surfactants, or surface-active agents, reduce the surface stress of the fluid, helping with bubble security and advertising foam generation. Additionally, anxiety or blending procedures can enhance bubble development, typically exacerbating foam issues. The features of the liquid medium, including viscosity and density, additional impact foam actions; for instance, more thick fluids tend to trap air better, causing enhanced foam stability.

Recognizing these basic elements of foam development is vital for reliable foam control in chemical production. By recognizing the problems that promote foam advancement, producers can apply targeted approaches to reduce its negative results, therefore optimizing manufacturing processes and guaranteeing constant product high quality. This fundamental expertise is crucial prior to exploring particular techniques for controlling foam in commercial setups.

Selection of Anti-Foaming Representatives

When selecting anti-foaming representatives, it is important to consider the details characteristics of the chemical procedure and the kind of foam being produced (Foam Control). Numerous aspects influence the performance of an anti-foaming representative, including its chemical structure, temperature stability, and compatibility with other process products

Silicone-based anti-foams are extensively utilized due to their high effectiveness and broad temperature level array. They function by decreasing surface tension, allowing the foam bubbles to coalesce and damage more conveniently. Nevertheless, they may not appropriate for all applications, especially those entailing delicate formulas where silicone contamination is an issue.

On the other hand, non-silicone agents, such as mineral oils or organic compounds, can be advantageous in particular situations, specifically when silicone residues are undesirable. These representatives have a tendency to be much less effective at greater temperatures however can offer effective foam control in other conditions.

In addition, understanding the foam's beginning-- whether it occurs from aeration, anxiety, or chain reactions-- guides the choice procedure. Evaluating under real operating problems is vital to make sure that the picked anti-foaming representative meets the distinct demands of the chemical production procedure successfully.

Refine Optimization Methods

Reliable foam control is an important element of optimizing chemical production processes. By fine-tuning these specifications, drivers can reduce disturbance, thus decreasing foam development throughout blending.

In addition, controlling temperature level and stress within the system can considerably affect foam generation. Reducing the temperature level might lower the volatility of particular elements, causing decreased foam. Also, maintaining optimum pressure levels helps in reducing excessive gas release, which adds to foam stability (Foam Control).

One more effective approach is the strategic addition of anti-foaming agents at critical points of the procedure. Mindful timing and dosage can make certain that these agents successfully subdue foam without interfering with various other process parameters.

Moreover, incorporating a systematic examination of resources residential or commercial properties can help identify inherently frothing substances, permitting preemptive measures. Performing regular audits and procedure evaluations can disclose inadequacies and areas for enhancement, making it possible for constant optimization of foam control strategies.

Monitoring and Control Equipment

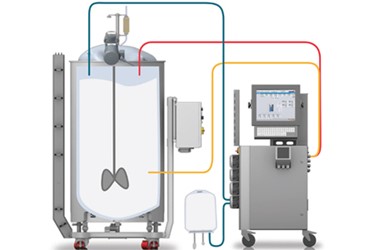

Surveillance and control systems play an essential role in maintaining optimal foam administration throughout the chemical production process. These systems are vital for real-time observation and adjustment of foam levels, ensuring that production performance is made the most of while lessening interruptions triggered by excessive foam development.

Advanced sensing units and instrumentation are utilized to detect foam density and elevation, supplying important information that informs control algorithms. This data-driven approach enables the timely application of antifoaming representatives, ensuring that foam levels continue to be within appropriate limits. By integrating surveillance systems with procedure control software application, suppliers can implement automated actions to foam fluctuations, reducing the requirement for hands-on intervention and improving functional uniformity.

In addition, the integration of device understanding and anticipating analytics into checking systems can facilitate positive foam management. By assessing historical foam data and operational parameters, these systems why not try here can anticipate foam generation patterns and advise preemptive procedures. Regular calibration and upkeep of surveillance equipment are necessary to make sure precision and dependability in foam detection.

Eventually, effective monitoring and control systems are important for maximizing foam control, promoting security, and boosting general productivity in chemical manufacturing environments.

Instance Research Studies and Best Practices

Real-world applications of monitoring and control systems highlight the significance of foam management in chemical manufacturing. A remarkable study involves a massive pharmaceutical supplier that applied an automated foam discovery system. By integrating real-time monitoring with predictive analytics, the facility reduced foam-related production downtime by 30%. The data-driven strategy enabled for timely interventions, making sure constant item quality and operational performance.

One more exemplary case originates from a petrochemical company that took on a combination of antifoam agents and procedure optimization strategies. By assessing foam generation patterns, the company tailored its antifoam dosage, resulting in a 25% reduction in chemical usage and substantial cost savings. This targeted strategy not only decreased foam interference but also improved the general security of the production process.

Verdict

Finally, attaining optimum foam control in chemical production requires an extensive technique including the selection of appropriate anti-foaming representatives, execution of process optimization strategies, and the combination of sophisticated monitoring systems. Normal audits and training even more enhance the performance of these techniques, fostering a society of continual enhancement. By addressing foam development proactively, producers can dramatically enhance production efficiency and item high quality, inevitably adding to more economical and lasting operations.

By comprehending the mechanisms of foam formation and picking ideal anti-foaming agents, producers can take positive procedures to mitigate excessive foam. The features of the fluid medium, including viscosity and density, more impact foam behavior; for instance, more thick liquids have a tendency to trap air a lot more properly, leading to enhanced foam security.

Recognizing these basic elements of foam formation is crucial for effective foam control in chemical manufacturing. By examining historic foam data and functional parameters, these systems can forecast foam generation patterns and recommend preemptive steps. Foam Control. Regular audits of foam control gauges guarantee that processes continue to be enhanced, while why not try this out fostering a society of aggressive foam monitoring can lead to lasting enhancements throughout the manufacturing range